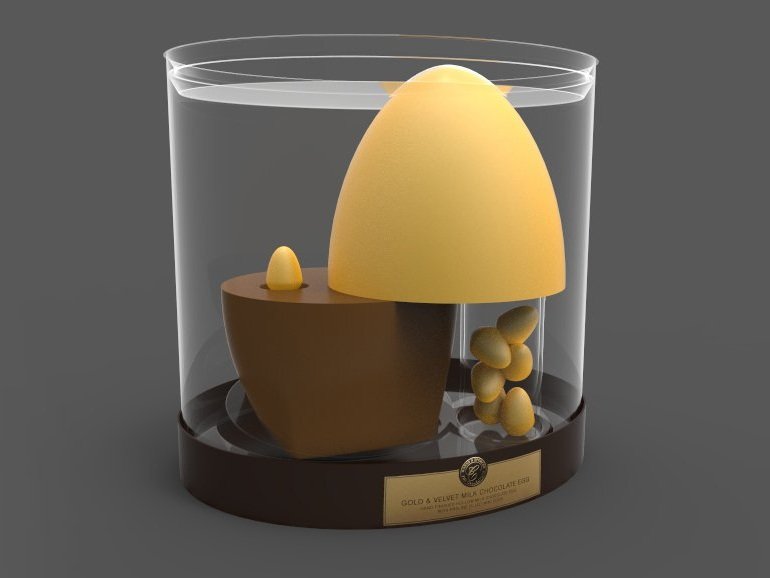

Easter Egg Packaging

Marks & Spencer

For 2 years the M&S Gold & Velvet Easter Egg failed to progress through transit testing.

Working closely in collaboration with a European supplier for innovative packaging solutions, I was able to create a solution that not only enabled the product to finally reach shelves, but was also featured in an M&S TV commercial.

The Brief

Eggs, and their ‘egg’ shape are naturally robust and good at resisting impact. Change the shape and structure, and usually the integrity of the structure suffers.

For two years running this particular split egg confectionary product had failed make it to store shelves intact.

Design a packaging solution that provides full visibility of the product, whilst also ensuring the egg arrives in store undamaged and in the correct orientation.

An example of previous packaging solutions after transit testing.

After analysing a number of transit tests, the problem became apparent. The tube of smaller eggs would punch through the underside of the top egg if any vertical impact occurred. This occurrence was inevitable given the way eggs are packed onto pallets and transported.

I theorised that by using a sheet of material, it was possible to disperse the impact over a wider area, preventing the underside from rupturing. In addition to this, fixing the top and bottom of the split egg would ensure that it remained intact.

After trialling and testing this theory we found the solution to work.

The split egg, and two other confectionary products I worked on after successfully making it through the first round of transit testing.